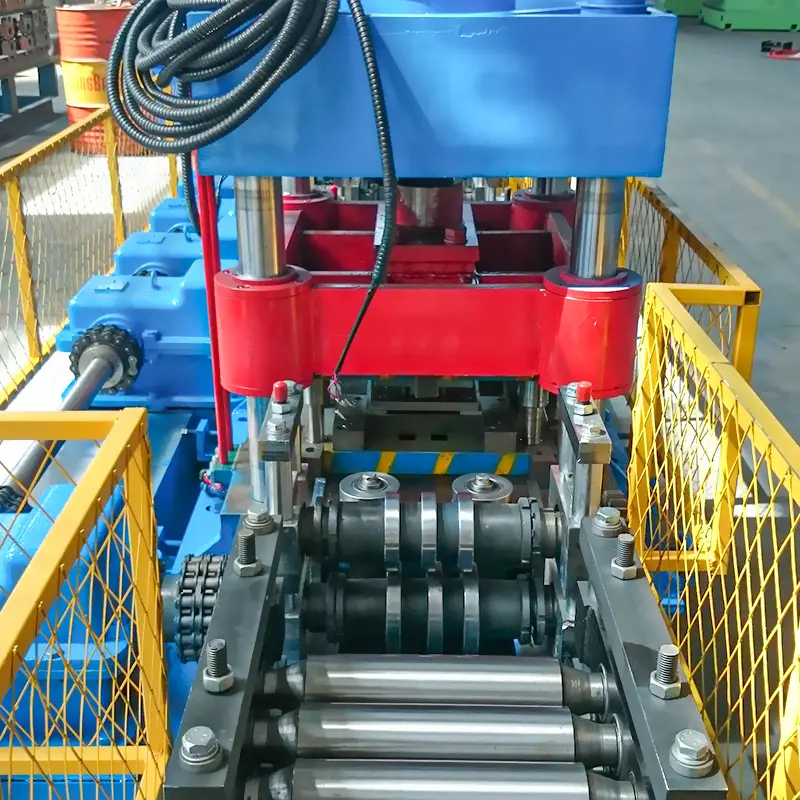

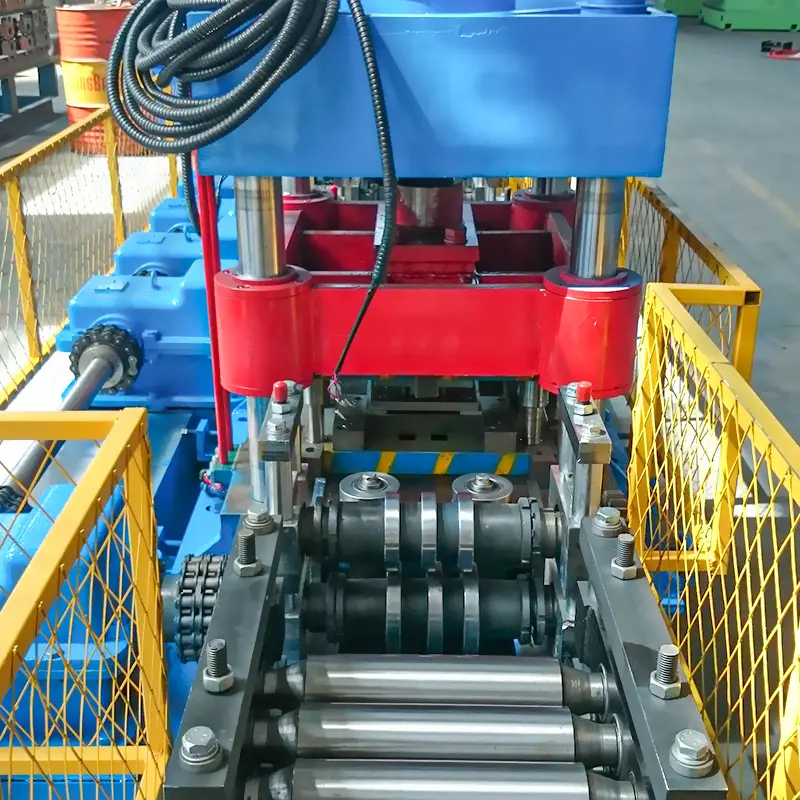

Roll Forming Machine Maintenance: Tips and Best Practices

Roll forming machines are essential equipment in many manufacturing industries, used for shaping metal sheets into various profiles and shapes. Like any machinery, roll forming machines require regular maintenance to ensure optimal performance and prevent downtime. Failure to properly maintain these machines can result in costly repairs, decreased productivity, and even safety hazards.

Maintenance tasks such as cleaning, lubricating, and inspecting the machine can help prevent wear and tear, reduce the risk of breakdowns, and extend the lifespan of the equipment. However, the maintenance requirements of roll forming machines can vary depending on factors such as the type of machine, the frequency of use, and the environment in which it operates.

Therefore, it is essential for businesses to establish a regular maintenance schedule and train operators on proper use and maintenance practices. By doing so, they can ensure that their roll forming machines are running smoothly and efficiently, and minimize the risk of unexpected downtime and costly repairs.

Daily Maintenance Checklist of Roll Forming Machine

Here is a sample daily maintenance checklist for roll forming machines that operators can follow:

- Check oil levels: Make sure that the oil levels are within the recommended range. Top up the oil if necessary.

- Inspect for signs of wear and tear: Check for any signs of wear and tear, such as cracks, rust, or damaged components. Report any abnormalities to the maintenance team.

- Tighten loose bolts: Inspect the machine for any loose bolts or fasteners and tighten them if necessary.

- Clean the machine: Wipe down the machine and remove any debris or dust that may have accumulated. Pay special attention to the rollers, guides, and other moving parts.

- Lubricate moving parts: Apply lubricant to the rollers, guides, and other moving parts to prevent friction and wear.

- Check safety features: Verify that all safety features, such as emergency stop buttons and guards, are working correctly.

- Record maintenance activities: Keep a log of all maintenance activities performed, including any abnormalities or issues identified.

By following this daily maintenance checklist, operators can help ensure that the roll forming machine is running smoothly and efficiently, and reduce the risk of unexpected downtime or breakdowns. It is important to train operators on the proper use and maintenance of the machine to ensure that the checklist is followed consistently and correctly.

weekly Maintenance Checklist of Roll Forming Machine

Forming Machine 5" width="800" height="800" />

Forming Machine 5" width="800" height="800" />

Here is a sample weekly maintenance checklist for roll forming machines that covers more in-depth maintenance tasks:

- Clean the machine: Thoroughly clean the machine, including the rollers, guides, and other moving parts. Use a degreaser or cleaning solution if necessary.

- Lubricate moving parts: Apply lubricant to all moving parts, including the rollers, guides, and chains. Check for any parts that need additional lubrication.

- Inspect electrical system: Check the electrical system for any loose wires, damaged cables, or signs of wear and tear. Inspect the control panel and other electrical components.

- Check belts and pulleys: Inspect belts and pulleys for any signs of wear and tear or damage. Tighten loose belts or replace them if necessary.

- Inspect bearings: Inspect all bearings for any signs of wear and tear or damage. Replace any damaged bearings.

- Check alignment: Verify that the machine is properly aligned and that all components are in their correct positions.

- Test safety features: Test all safety features, including emergency stop buttons and safety guards, to ensure that they are working correctly.

- Record maintenance activities: Keep a log of all maintenance activities performed, including any abnormalities or issues identified.

By following this weekly maintenance checklist, operators can help ensure that the roll forming machine is running smoothly and efficiently, and reduce the risk of unexpected downtime or breakdowns. It is important to train operators on the proper use and maintenance of the machine to ensure that the checklist is followed consistently and correctly. Regular maintenance can help extend the lifespan of the machine and reduce repair costs over time.

Forming Machine 5" width="800" height="800" />

Forming Machine 5" width="800" height="800" />